They are installed beneath the visible flooring material, meaning that the desired flooring-whether elegant hardwood, practical laminate, or cozy carpet-remains unaltered. Soundproofing Material Products from this Soundproofing Supplier are affective acoustic solutions. Environmental considerations are central to the design of acoustic underlays. The materials used in acoustic underlays, such as foam, cork, and natural rubber, are effective in reducing vibrations and controlling sound. Buildtec Acoustics offers a variety of acoustic underlays to meet different needs, including those designed for underfloor heating systems. This allows consumers to achieve their preferred aesthetics without sacrificing soundproofing performance. Buildtec Acoustics offers underlays made from environmentally friendly materials, such as cork, recycled crumb rubber, and natural wool.

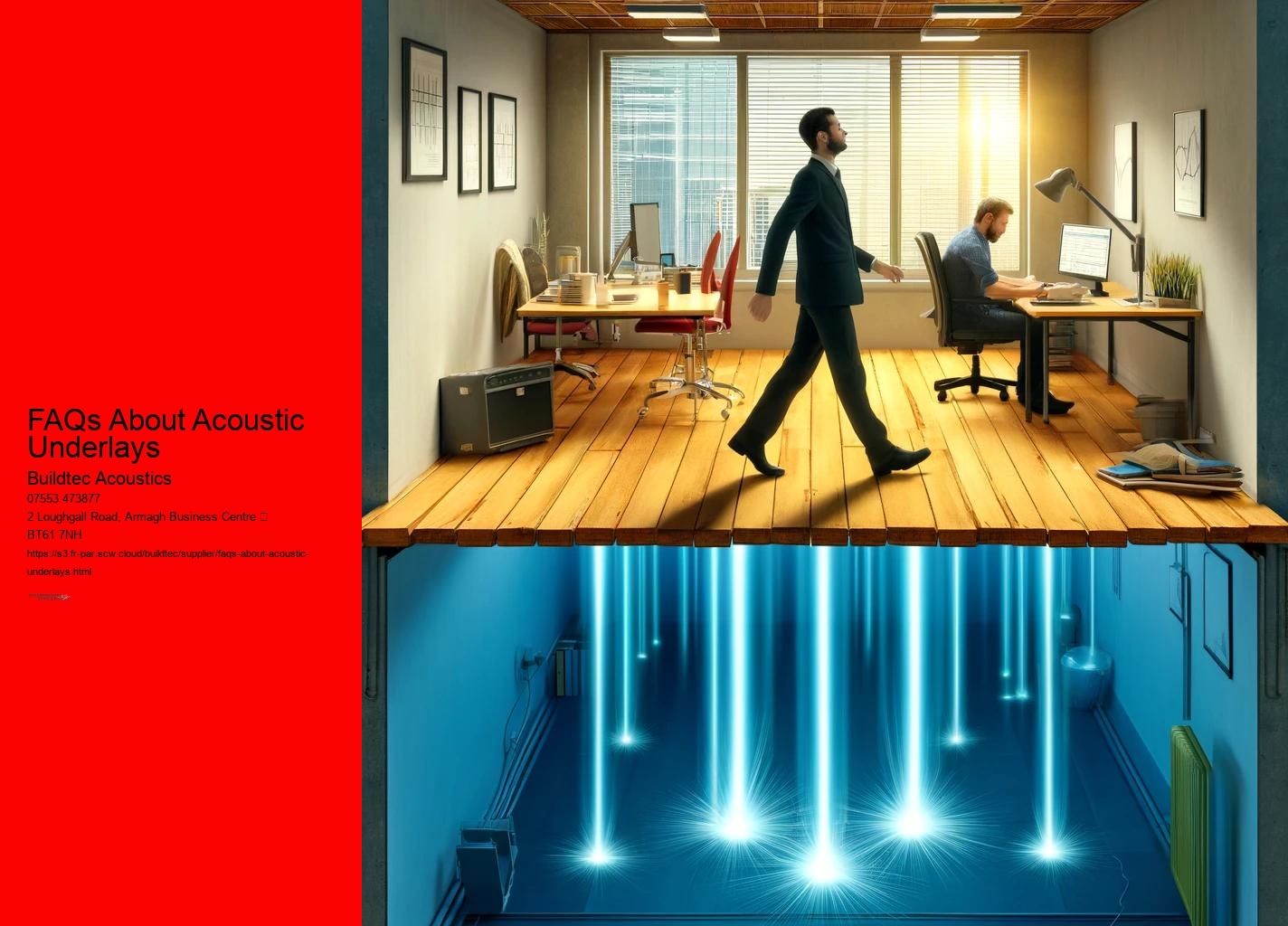

The primary function of acoustic underlay is to address both impact noise and airborne sound. This process involves the transformation of sound energy into heat, which then dissipates harmlessly. Adhesive or double-sided tape can be used to secure the underlay in place, while maintaining tight seams between the pieces to prevent gaps that may impact performance.

FAQs About Acoustic Underlays - noise control

- membrane

- solvent

- underfloor heating

Acoustic underlays operate by absorbing and dissipating sound energy, which reduces noise transmission through floors. silence Most underlays come in sheets or rolls and can be cut to size using simple tools like a utility knife. Whether the flooring type is laminate, ceramic, or hardwood, Buildtec Acoustics provides underlays specifically designed to complement the chosen material. Most underlays come in sheet or roll form and can be cut to size with simple tools like a utility knife. By utilizing high-density materials like crumb rubber and cork, acoustic underlays offer efficient noise control, reducing the impact of noise on people in adjacent rooms or units.

Additionally, these materials are low in volatile organic compound (VOC) emissions, contributing to a healthier indoor environment. concrete Acoustic underlays function by absorbing and dissipating sound energy, which helps to minimize noise transmission through floors.

FAQs About Acoustic Underlays - concrete

- adhesive

- polyvinyl chloride

- mineral wool

- vibration isolation

- single-family detached home

- cushion

- heating equipment

FAQs About Acoustic Underlays - telephone

- melody

- virtuoso

- symphony

- thermal insulation

- membrane

- solvent

- underfloor heating