Whether it's about the timing, the process, or how they'll manage potential issues, having a clear understanding will help set your mind at ease. Learn more about Surrey Polybutylene Pipe Replacement Company here As you navigate the complexities of maintaining or updating your home, it's crucial to grasp why replacing these pipes isn't just a recommendation but a necessity. Next, you'll agree on a timeline that minimizes disruption to residents. Their approach is detail-oriented, starting with a thorough assessment of your current piping system.

Our professionals regularly attend workshops and seminars to update their skills and knowledge, ensuring they're always prepared with the most effective solutions for your polybutylene pipe issues. That's the harsh reality for many homeowners in Surrey Polybutylene Pipe Replacement Company dealing with polybutylene pipes. These audits help identify potential hazards before they become problems.

They'll start with a thorough inspection of your property to identify all the polybutylene piping needing replacement. Learn more about Canyon Property Projects Ltd. here. Polybutylene is a type of plastic that was widely used in plumbing systems from the 1970s until the mid-1990s.

Lastly, you might even see a reduction in your water bills. Since polybutylene pipes often fail internally, you mightn't see the problem until it's reflected in your costs. This means more enjoyable showers and more efficient water usage. The culprit?

The benefits for strata councils in Surrey Polybutylene Pipe Replacement Company extend far beyond simple pipe replacement, touching on aspects of project management, resident satisfaction, and long-term property integrity. Moreover, updated plumbing systems can significantly increase a property's market value. What sets Canyon Property apart is their commitment to using the latest technology and materials that guarantee longevity and reliability.

It's a proactive step to prevent water damage, maintain your property's value, and ensure a safe living environment. They've also embraced trenchless technology for replacements wherever possible. Once your service is scheduled, they'll send you a confirmation email or text, depending on your preference, with all the details of your appointment. We'll keep you informed throughout the preparation phase, providing clear instructions on how you can assist, if necessary. Opting for a proactive approach not only saves you from potential water damage but also enhances your home's value and plumbing system's reliability.

Our process involves carefully removing the old polybutylene pipes, minimizing disruption to your home and daily routine.

Insurance companies often lower rates for properties that proactively mitigate risks, such as replacing outdated polybutylene piping. Before exploring how to address the issues with polybutylene, it's essential you understand what these pipes are and why they were so widely used. Smaller homes can often see a complete replacement done in less than a week, while larger properties or those with more complex layouts may require a bit more time. Having understood the value polybutylene pipe replacement adds, let's focus on how quickly Canyon Property Projects Ltd. can begin enhancing your property. This upgrade signals to potential buyers that you've invested in the longevity and safety of the home, making it a more attractive purchase.

You're likely wondering about the specifics. Moreover, insurance premiums could drop once you've replaced high-risk polybutylene with more durable materials. They're bringing their renowned quality and efficiency to more locations, ensuring that your property is protected, regardless of where you're located. When you choose us, you're not just getting a service; you're tapping into a wealth of knowledge and skill that's been honed over countless successful projects.

Don't wait for a disaster to strike.

After preparing your property, let's explore our service coverage areas, starting with Surrey Polybutylene Pipe Replacement Company. Insurance companies often favor homes with updated plumbing, potentially lowering your premiums. They navigate the complexities of working with strata councils and property managers, ensuring clear communication and collaboration at every step. You might not be aware that many homes and businesses in Surrey Polybutylene Pipe Replacement Company are still relying on polybutylene pipes, a material once popular for its low cost but now known for its high risk of failure. This is because newer materials don't corrode or degrade as quickly, leading to fewer contaminants in your water supply.

Whether you're nestled in the heart of Surrey Polybutylene Pipe Replacement Company or situated in the surrounding communities, their expanded coverage ensures that your property's plumbing needs are well within reach.

Lastly, new pipes can improve your home's water pressure, making showers more enjoyable and efficient. The size of your property and the complexity of the plumbing system play significant roles in determining the completion time. Safety regulations in plumbing If you spot any damp patches on your walls or ceiling, or notice a musty smell, it's time to act fast. Their expertise not only addresses the immediate concerns of potential property damage but also brings a long-term peace of mind. Typically, the actual replacement process is streamlined to minimize downtime.

It's reshaping how you think about home maintenance and safety. We'll help you understand the extent of polybutylene piping within your premises and the potential risks involved. If something goes wrong shortly after the installation, you won't have to foot the bill for repairs or replacements. It's important to remember that our team prioritizes minimizing disruption to your daily life.

Lastly, 'What materials do you use for replacement?' We use high-quality, durable materials like PEX or copper, ensuring your new plumbing system is robust and long-lasting. Then, the skilled technicians get to work. Switching to modern plumbing materials like PEX or copper can significantly cut down your long-term maintenance and repair costs. We've got transparency at the heart of our operations, so you're never left in the dark.

Our residents barely felt the transition,' she explains. Water supply systems Canyon Property Projects Ltd has streamlined their process, making it easier for you to schedule and receive the services you need, when you need them. Another strategy is to update your home's plumbing with newer, more durable materials. Their approach not only addresses the immediate leaks but also the underlying risks these pipes pose to your home's integrity and your peace of mind. Plumbing solutions

Our skilled technicians ensure a seamless transition from old to new, paying close attention to connections to your existing plumbing system. They understand you've got a community to manage, so they work swiftly and cleanly, ensuring residents or tenants face the least possible inconvenience. You'll want to keep an eye out for damp patches, mold growth, or a musty smell, which are telltale signs of hidden leaks. No matter which method you choose, Canyon Property Experts is committed to making the process as hassle-free as possible. Selecting the ideal material for your pipes is a critical step in the replacement process.

After understanding our comprehensive replacement process, let's explore the significant advantages that new piping can offer your home. Pipe insulation With Canyon Property Projects Ltd.'s expertise, you can make a decision that benefits your property now and in the future. Once the work is completed, you'll receive a final walkthrough to confirm everything meets your expectations.

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

A contractor[1][2] (North American English) or builder (British English),[3][4] is responsible for the day-to-day oversight of a construction site, management of vendors and trades, and the communication of information to all involved parties throughout the course of a building project.[5]

In the United States, a contractor may be a sole proprietor managing a project and performing labor or carpentry work, have a small staff, or may be a very large company managing billion dollar projects. Some builders build new homes, some are remodelers, some are developers.[6]

A general contractor is a construction manager employed by a client, usually upon the advice of the project's architect or engineer.[7] General Contractors are mainly responsible for the overall coordination of a project and may also act as building designer and construction foreman (a tradesman in charge of a crew).

A general contractor must first assess the project-specific documents (referred to as a bid, proposal, or tender documents). In the case of renovations, a site visit is required to get a better understanding of the project. Depending on the project delivery method, the general contractor will submit a fixed price proposal or bid, cost-plus price or an estimate. The general contractor considers the cost of home office overhead, general conditions, materials, and equipment, as well as the cost of labor, to provide the owner with a price for the project.

Contract documents may include drawings, project manuals (including general, supplementary, or special conditions and specifications), and addendum or modifications issued prior to proposal/bidding and prepared by a design professional, such as an architect.The general contractor may also assume the role of construction manager, responsible for overseeing the project while assuming financial and legal risks.There are several types of risks can occur include cost overruns, delays, and liabilities related to safety or contract breaches.

Prior to formal appointment, the selected general contractor to whom a client proposes to award a contract is often referred to as a "preferred contractor".[8]

A general contractor is responsible for providing all of the material, labor, equipment (such as heavy equipment and tools) and services necessary for the construction of the project. A general contractor often hires specialized subcontractors to perform all or portions of the construction work. When using subcontractors, the general contractor is responsible for overseeing the quality of all work performed by any and all of the workers and subcontractors.

It is a best practice for general contractors to prioritize safety on the job site, and they are generally responsible for ensuring that work takes place following safe practices.

A general contractor's responsibilities may include applying for building permits, advising the person they are hired by, securing the property, providing temporary utilities on site, managing personnel on site, providing site surveying and engineering, disposing or recycling of construction waste, monitoring schedules and cash flows, and maintaining accurate records.[9]

The general contractor may be responsible for some part of the design, referred to as the "contractor's design portion" (JCT terminology).[10]

In the United Kingdom, Australia and some British Commonwealth countries, the term 'general contractor' was gradually superseded by builders during the early twentieth century.[citation needed] This was the term used by major professional, trade, and consumer organizations when issuing contracts for construction work, and thus the term 'general contractor' fell out of use except in large organizations where the main contractor is the top manager and a general contractor shares responsibilities with professional contractors.

General contractors who conduct work for government agencies are often referred to as "builders". This term is also used in contexts where the customer's immediate general contractor is permitted to sub-contract or circumstances are likely to involve sub-contracting to specialist operators e.g. in various public services.

In the United States and Asia, the terms general contractor (or simply "contractor"), prime contractor and main contractor are often interchangeable when referring to small local companies that perform residential work. These companies are represented by trade organizations such as the NAHB.[11]

Prime contractor is a term defined in the US law.[12][13] Statutory definitions of prime contract, prime contractor, subcontract, and subcontractor are in 41 U.S.C. § 8701.[14] The prime contractor term was already defined before the 8 March 1946 passage of An Act To eliminate the practice by subcontractors, under cost-plus-a-fixed-fee or cost reimbursable contacts of the United States, of paying fees or kick-backs, or of granting gifts or gratuities to employees of a cost-plus-a-fixed-fee or cost reimbursable prime contractors or of higher tier subcontractors for the purpose of securing the award of subcontracts or orders. (Pub. L.Tooltip Public Law (United States) 79–319, 60 Stat. 37)

Licensing requirements to work legally on construction projects vary from locale to locale. In the United States, there are no federal licensing requirements to become a general contractor, but most US states require general contractors to obtain a local license to operate. It is the states' responsibility to define these requirements: for example, in the state of California, the requirements are stated as follows:

With a few exceptions, all businesses or individuals who work on any building, highway, road, parking facility, railroad, excavation, or other structure in California must be licensed by the California Contractors State License Board (CSLB) if the total cost of one or more contracts on the project is $500 or more.

In every state that requires a license, a surety bond is required as part of the licensing process, with the exception of Louisiana, where bonding requirements may vary in different parishes. Not all states require General Contractor licenses - these include Vermont, New Hampshire and Maine, among others.

Some general contractors obtain bachelor's degrees in construction science, building science, surveying, construction safety, or other disciplines.

General Contractors often learn about different aspects of construction, including masonry, carpentry, framing, and plumbing. Aspiring general contractors communicate with subcontractors and may learn the management skills they need to run their own company.

Experience in the construction industry as well as references from customers, business partners, or former employers are demanded. Some jurisdictions require candidates to provide proof of financing to own their own general contracting firm.

General Contractors often run their own business. They hire subcontractors to complete specialized construction work and may manage a team of plumbers, electricians, bricklayers, carpenters, iron workers, technicians, handymans, architects and roofers. General Contractors build their business by networking with potential clients, buying basic construction tools, and ensuring that their subcontractors complete high-quality work. General Contractors do not usually complete much construction work themselves, but they need to be familiar with construction techniques so they can manage workers effectively. Other reasons include access to specialist skills, flexible hiring and firing, and lower costs.

A property owner or real estate developer develops a program of their needs and selects a site (often with an architect). The architect assembles a design team of consulting engineers and other experts to design the building and specify the building systems. Today contractors frequently participate on the design team by providing pre-design services such as providing estimations of the budget and scheduling requirements to improve the economy of the project. In other cases, the general contractor is hired at the close of the design phase. The owner, architect, and general contractor work closely together to meet deadlines and budget. The general contractor works with subcontractors to ensure quality standards; subcontractors specialise in areas such as electrical wiring, plumbing, masonry, etc.

| |

| Names | |

|---|---|

| Other names

polybutene-1, poly(1-butene), PB-1

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.111.056 |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C4H8)n | |

| Density | 0.95 g/cm3[1] |

| Melting point | 135 °C (275 °F; 408 K)[1] |

| Related compounds | |

Related compounds

|

1-butene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

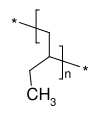

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.[2]

Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts.

Isotactic PB-1 is produced commercially using two types of heterogeneous Ziegler–Natta catalysts.[3] The first type of catalyst contains two components, a solid pre-catalyst, the δ-crystalline form of TiCl3, and solution of an organoaluminum cocatalyst, such as Al(C2H5)3. The second type of pre-catalyst is supported. The active ingredient in the catalyst is TiCl4 and the support is microcrystalline MgCl2. These catalysts also contain special modifiers, organic compounds belonging to the classes of esters or ethers. The pre-catalysts are activated by combinations of organoaluminum compounds and other types of organic or organometallic modifiers. Two most important technological advantages of the supported catalysts are high productivity and a high fraction of the crystalline isotactic polymer they produce at 70–80 °C under standard polymerization conditions.[4][5][6]

PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

PB-1, when applied as a pure or reinforced resin, can replace materials like metal, rubber and engineering polymers. It is also used synergistically as a blend element to modify the characteristics of other polyolefins like polypropylene and polyethylene. Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

Heated up to 190 °C and above, PB-1 can easily be compression moulded, injection moulded, blown to hollow parts, extruded, and welded. It does not tend to crack due to stress.[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.[7] It is flexible, resists impact well and has good elastic recovery.[3][8]

Isotactic polybutylene crystallizes in three different forms. Crystallization from solution yields form-III with the melting point of 106.5 °C. Cooling from the melt results in the form II which has melting point of 124 °C and density of 0.89 g/cm3. At room temperature, it spontaneously converts into the form-I with the melting point of 135 °C and density of 0.95 g/cm3.[1]

PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).[3] It shows lower resistance to aromatic and chlorinated hydrocarbons as well as oxidising acids than other polymers such as polysulfone and polyamide 6/6.[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers. It is compatible with polypropylene, ethylene propylene rubbers, and thermoplastic elastomers.

Some properties:[7]

The main use of PB-1 is in flexible pressure piping systems for hot and cold drinking water distribution, pre-insulated district heating networks and surface heating and cooling systems. ISO 15876 defines the performance requirements of PB-1 piping systems.[9] PB-1's most notable characteristics are weldability, temperature resistance, flexibility and high hydrostatic pressure resistance. The material can be classified PB 125 with a minimum required strength (MRS) of 12.5 MPa. Other features include low noise transmission, low linear thermal expansion, no corrosion and calcification.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below). The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years. In certain domestic markets, e.g. Kuwait, the United Kingdom, Korea and Spain, PB-1 piping systems have a strong position.[8]

Several PB-1 grades are commercially available for various applications and conversion technologies (blown film, cast film, extrusion coating). There are two main fields of application:

PB-1 is compatible with a wide range of tackifier resins. It offers high cohesive and adhesive strength and helps tailoring the "open time" of the adhesive (up to 30 minutes) because of its slow crystallisation kinetics. It improves the thermal stability and the viscosity of the adhesive.[10]

PB-1 accepts very high filler loadings in excess of 70%. In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments. PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

PB-1 can be foamed.[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.[12]

Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Plumbing and heating systems made from PB-1 have been used in Europe and Asia for more than 30 years. First reference projects in district heating and floor heating systems in Germany and Austria from the early 1970s are still in operation today.[8]

One example is the installation of PB-1 pipes in the Vienna Geothermal Project (1974) where aggressive geothermal water is distributed at a service temperature of 54 °C and 10 bar pressure. Other pipe materials in the same installation failed or corroded and had been replaced in the meantime.[8]

International standards set minimum performance requirements for pipes made from PB-1 used in hot water applications. Standardized extrapolation methods predict lifetimes in excess of 50 years at 70 °C and 10 bar.[8]

Polybutylene plumbing was used in several million homes built in the United States from around 1978 to 1997. Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.[13][14] The leaks were associated with degradation of polybutylene exposed to chlorinated water.[15]

Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing. The piping was removed from the acceptable for use list in the 2005 issue of the standard.[19]

In Australia in March 2023, the Department of Mines, Industry Regulation and Safety reported that Australian homes built in 2019-2020 that had used a certain brand of polybutylene piping, had become the subject of an enquiry due to the significance of water leaks reported.[20][21]

There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.[22] The reaction with chlorinated water appears to be greatly accelerated by tensile stress, and is most often observed in material under highest mechanical stress such as at fittings, sharp bends, and kinks. Localized stress whitening of the material generally accompanies and precedes decomposition of the polymer. In extreme cases, this stress-activated chemical "corrosion" can lead to perforation and leakage within a few years, but it also may not fail for decades. Fittings with a soft compression seal can give adequate service life.[further explanation needed]

Because the chemical reaction of the water with the pipe occurs inside the pipe, it is often difficult to assess the extent of deterioration. The problem can cause both slow leaks and pipe bursting without any previous warning indication. The only long-term solution is to completely replace the polybutylene plumbing throughout the entire building.[23]

You're curious about long-term impacts, right? Replacing polybutylene pipes can significantly reduce your risk of water damage, increase property value, and ensure safer water quality for years. It's a smart move for any homeowner.

You'd be glad to know they use careful planning and communication to minimize disruption. They'll schedule work in phases, ensuring residents are informed and comfortable throughout the process, keeping your daily life as uninterrupted as possible.

Yes, they offer ongoing maintenance and monitoring services to catch and fix potential plumbing issues early in strata properties. This proactive approach helps avoid bigger problems and ensures your building's plumbing remains in top condition.