With Canyon Property Projects Ltd., your home improvement project is in hands that truly understand the value of tailoring everything to suit your individual needs and tastes. They understand the importance of your outdoor space being a personal retreat and a place for gathering, making every project they undertake uniquely tailored to fit your vision and lifestyle. They take your vision and turn it into reality, making sure every aspect of the project reflects your personal style while adding value to your home. Learn more about Home Remodeling Services Surrey here They're committed to using high-quality, durable materials that ensure your outdoor space not only looks fantastic but withstands the test of time. You're not just improving your space; you're investing in a home that's both personally satisfying and appealing to the Home Remodeling Services Surrey market.

It's not merely cosmetic; it's an investment in your home's future. Their team doesn't just fill rooms with furniture; they breathe life into your home, ensuring every corner reflects your individuality and lifestyle. During this meeting, you'll have the opportunity to share your vision, needs, and specific requirements. They're not just about solving problems; they're about preventing them. Smart home upgrades

You'll find their approach to technology integration isn't just about adding gadgets or the latest trends. You might not be aware, but Canyon Property Projects Ltd. has quietly risen as the undisputed leader in home improvement across Home Remodeling Services Surrey, setting standards that few can match. They communicate effectively, keeping you in the loop at every stage of the process. In essence, Canyon Property Projects Ltd doesn't just renovate homes; they're building a greener, more sustainable world, one project at a time.

Firstly, updating your siding or facade can make a world of difference. Think of your home's exterior as its face. Canyon Property Projects Ltd. Open concept renovation partners with reputable suppliers, ensuring that only the highest quality materials make it into your project. While focusing on your unique needs, Canyon Property Projects Ltd also ensures unparalleled quality and craftsmanship in every project they undertake. Learn more about Canyon Property Projects Ltd. here.

However, with Canyon Property Projects Ltd. at your helm in Home Remodeling Services Surrey, you're equipped with a compass that points straight to success. They're constantly pushing the envelope, incorporating the latest techniques and materials to ensure your home not only looks fantastic but is also built to last.

By selecting materials that aren't only durable but also sourced responsibly, they make sure your renovation isn't just beautiful-it's also kind to the planet. Continue to uncover how their blend of quality, creativity, and client-focused approach could redefine your property's potential. Plus, they're flexible, ready to adjust plans as your needs evolve during the project. This comprehensive approach to quality control sets Canyon Property Projects Ltd. apart, making them a leader in Home Remodeling Services Surrey home improvement. Our team's expertise spans across all areas of home improvement, from initial design and planning to the final touches of decoration.

This means you're not just getting quality as it's known today but a forward-thinking approach that anticipates the needs and standards of tomorrow.

At its core, Canyon Property Projects Ltd aims to enhance the comfort and value of homes across Home Remodeling Services Surrey with top-notch renovation and customization services. This is the reality that Canyon Property Projects Ltd. is creating for homeowners across Home Remodeling Services Surrey. They don't cut corners or settle for 'good enough'. With a team of highly skilled professionals, you're not just getting a contractor; you're partnering with artisans who view their work as a blend of art and science. Aging-in-place renovations Whether you're dreaming of a minimalist living room, a rustic kitchen, or a luxurious bathroom, they've got the expertise to turn your vision into reality.

They're committed to bringing your vision to life, incorporating your personal style into the design while pushing the boundaries of what's possible. They're committed to a construction process that minimizes waste and maximizes recycling. Laminate flooring installation They understand that the backbone of any successful renovation or construction project lies not just in the expertise of their team but also in the quality of materials and tools used. Our team is made up of experienced professionals who take pride in their work, adhering to strict timelines and budget constraints without compromising on quality.

By identifying key areas for improvement, such as modernizing kitchens and bathrooms, upgrading heating and cooling systems, and enhancing outdoor living spaces, you can expect a considerable return on investment (ROI). They're also adept at addressing structural issues, offering solutions that not only improve the appearance of your home but also its safety and durability. Stay with us as we explore the intricate details of their approach, from the initial design concept to the exceptional aftercare services that leave clients in awe long after the project is completed. It's this dedication to your satisfaction that sets Canyon Property Projects Ltd. apart, making them a trusted choice for your home improvement needs.

Ensuring your complete satisfaction is our top priority at Canyon Property Projects Ltd., where we believe in turning your home improvement dreams into reality with precision and care. You'll receive regular updates, so you're always in the loop. Their electricians and plumbers are second to none, ensuring that the nuts and bolts of your home are functioning perfectly. You'll find that our work spans across various styles and preferences, whether you're looking for a sleek contemporary bathroom upgrade or a traditional living room revamp.

You'll find their attention to detail impeccable.

With Canyon Property Projects Ltd., you're not just renovating your space; you're elevating your living experience. Imagine transforming your bathroom into a spa-like retreat where every detail reflects your personal style and meets your functional needs. This gallery isn't just inspiring; it's a testament to the transformative power of skilled home improvement. With Canyon Property Projects Ltd., you're not just getting a contractor; you're gaining a partner invested in the lasting quality and satisfaction of your home improvement project. With a keen eye for detail and a commitment to using high-quality materials and craftsmanship, Canyon Property Projects ensures that every aspect of your renovation is handled with the utmost professionalism.

Moreover, we stand behind our work with a robust aftercare service, ready to address any concerns or adjustments you may desire post-completion. From securing necessary permits to the final touches, they'll manage every aspect, making the process as stress-free as possible for you. Canyon Property Projects Ltd. offers a wide array of renovation services, ensuring your home not only functions optimally but also aligns with your aesthetic preferences. That's why we don't cut corners.

From upgrading insulation to installing high-efficiency windows and doors, they've got you covered. With a keen eye for detail, they ensure that every project, whether it's a state-of-the-art kitchen, a luxurious bathroom, or an entire home makeover, exceeds their clients' expectations. Therefore, we work diligently to avoid such setbacks, keeping you informed every step of the way. This team doesn't just work for you; they collaborate with you, making sure that every aspect of the project meets your standards and surpasses your expectations. Read more about Home Remodeling Services Surrey here

That's why they never cut corners, selecting materials that not only look great but also stand the test of time. They understand that questions and concerns can arise after the job is done. Let them help you make your dream home a reality. You'll find their team responsive and attentive, breaking down complex project details into understandable terms, ensuring you're always in the loop. Bathroom renovation

Understanding your unique needs, Canyon Property Projects Ltd. tailors every home improvement solution specifically for you. You, as a realtor or property owner in Home Remodeling Services Surrey, understand the significance of customization in today's dynamic real estate market. Maybe you're aiming for an energy-efficient upgrade to cut down on utility bills. With Canyon Property Projects, you're not just getting a service; you're investing in a partner who values your time and investment as much as you do. Just as they've mastered the art of creating custom kitchens, Canyon Property Projects Ltd. now offers the same level of expertise and personalization for luxurious bathroom upgrades.

From the initial consultation to the final walkthrough, you're in capable hands. This holistic approach is what sets them apart in the Home Remodeling Services Surrey home improvement scene. You'll find they use only top-grade materials that guarantee durability and aesthetics.

| |

| Names | |

|---|---|

| Other names

polybutene-1, poly(1-butene), PB-1

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.111.056 |

CompTox Dashboard (EPA)

|

|

| Properties | |

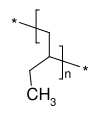

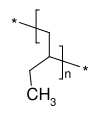

| (C4H8)n | |

| Density | 0.95 g/cm3[1] |

| Melting point | 135 °C (275 °F; 408 K)[1] |

| Related compounds | |

Related compounds

|

1-butene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.[2]

Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts.

Isotactic PB-1 is produced commercially using two types of heterogeneous Ziegler–Natta catalysts.[3] The first type of catalyst contains two components, a solid pre-catalyst, the δ-crystalline form of TiCl3, and solution of an organoaluminum cocatalyst, such as Al(C2H5)3. The second type of pre-catalyst is supported. The active ingredient in the catalyst is TiCl4 and the support is microcrystalline MgCl2. These catalysts also contain special modifiers, organic compounds belonging to the classes of esters or ethers. The pre-catalysts are activated by combinations of organoaluminum compounds and other types of organic or organometallic modifiers. Two most important technological advantages of the supported catalysts are high productivity and a high fraction of the crystalline isotactic polymer they produce at 70–80 °C under standard polymerization conditions.[4][5][6]

PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

PB-1, when applied as a pure or reinforced resin, can replace materials like metal, rubber and engineering polymers. It is also used synergistically as a blend element to modify the characteristics of other polyolefins like polypropylene and polyethylene. Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

Heated up to 190 °C and above, PB-1 can easily be compression moulded, injection moulded, blown to hollow parts, extruded, and welded. It does not tend to crack due to stress.[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.[7] It is flexible, resists impact well and has good elastic recovery.[3][8]

Isotactic polybutylene crystallizes in three different forms. Crystallization from solution yields form-III with the melting point of 106.5 °C. Cooling from the melt results in the form II which has melting point of 124 °C and density of 0.89 g/cm3. At room temperature, it spontaneously converts into the form-I with the melting point of 135 °C and density of 0.95 g/cm3.[1]

PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).[3] It shows lower resistance to aromatic and chlorinated hydrocarbons as well as oxidising acids than other polymers such as polysulfone and polyamide 6/6.[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers. It is compatible with polypropylene, ethylene propylene rubbers, and thermoplastic elastomers.

Some properties:[7]

The main use of PB-1 is in flexible pressure piping systems for hot and cold drinking water distribution, pre-insulated district heating networks and surface heating and cooling systems. ISO 15876 defines the performance requirements of PB-1 piping systems.[9] PB-1's most notable characteristics are weldability, temperature resistance, flexibility and high hydrostatic pressure resistance. The material can be classified PB 125 with a minimum required strength (MRS) of 12.5 MPa. Other features include low noise transmission, low linear thermal expansion, no corrosion and calcification.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below). The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years. In certain domestic markets, e.g. Kuwait, the United Kingdom, Korea and Spain, PB-1 piping systems have a strong position.[8]

Several PB-1 grades are commercially available for various applications and conversion technologies (blown film, cast film, extrusion coating). There are two main fields of application:

PB-1 is compatible with a wide range of tackifier resins. It offers high cohesive and adhesive strength and helps tailoring the "open time" of the adhesive (up to 30 minutes) because of its slow crystallisation kinetics. It improves the thermal stability and the viscosity of the adhesive.[10]

PB-1 accepts very high filler loadings in excess of 70%. In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments. PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

PB-1 can be foamed.[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.[12]

Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Plumbing and heating systems made from PB-1 have been used in Europe and Asia for more than 30 years. First reference projects in district heating and floor heating systems in Germany and Austria from the early 1970s are still in operation today.[8]

One example is the installation of PB-1 pipes in the Vienna Geothermal Project (1974) where aggressive geothermal water is distributed at a service temperature of 54 °C and 10 bar pressure. Other pipe materials in the same installation failed or corroded and had been replaced in the meantime.[8]

International standards set minimum performance requirements for pipes made from PB-1 used in hot water applications. Standardized extrapolation methods predict lifetimes in excess of 50 years at 70 °C and 10 bar.[8]

Polybutylene plumbing was used in several million homes built in the United States from around 1978 to 1997. Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.[13][14] The leaks were associated with degradation of polybutylene exposed to chlorinated water.[15]

Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing. The piping was removed from the acceptable for use list in the 2005 issue of the standard.[19]

In Australia in March 2023, the Department of Mines, Industry Regulation and Safety reported that Australian homes built in 2019-2020 that had used a certain brand of polybutylene piping, had become the subject of an enquiry due to the significance of water leaks reported.[20][21]

There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.[22] The reaction with chlorinated water appears to be greatly accelerated by tensile stress, and is most often observed in material under highest mechanical stress such as at fittings, sharp bends, and kinks. Localized stress whitening of the material generally accompanies and precedes decomposition of the polymer. In extreme cases, this stress-activated chemical "corrosion" can lead to perforation and leakage within a few years, but it also may not fail for decades. Fittings with a soft compression seal can give adequate service life.[further explanation needed]

Because the chemical reaction of the water with the pipe occurs inside the pipe, it is often difficult to assess the extent of deterioration. The problem can cause both slow leaks and pipe bursting without any previous warning indication. The only long-term solution is to completely replace the polybutylene plumbing throughout the entire building.[23]

| |

| Names | |

|---|---|

| Other names

polybutene-1, poly(1-butene), PB-1

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.111.056 |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C4H8)n | |

| Density | 0.95 g/cm3[1] |

| Melting point | 135 °C (275 °F; 408 K)[1] |

| Related compounds | |

Related compounds

|

1-butene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.[2]

Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts.

Isotactic PB-1 is produced commercially using two types of heterogeneous Ziegler–Natta catalysts.[3] The first type of catalyst contains two components, a solid pre-catalyst, the δ-crystalline form of TiCl3, and solution of an organoaluminum cocatalyst, such as Al(C2H5)3. The second type of pre-catalyst is supported. The active ingredient in the catalyst is TiCl4 and the support is microcrystalline MgCl2. These catalysts also contain special modifiers, organic compounds belonging to the classes of esters or ethers. The pre-catalysts are activated by combinations of organoaluminum compounds and other types of organic or organometallic modifiers. Two most important technological advantages of the supported catalysts are high productivity and a high fraction of the crystalline isotactic polymer they produce at 70–80 °C under standard polymerization conditions.[4][5][6]

PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

PB-1, when applied as a pure or reinforced resin, can replace materials like metal, rubber and engineering polymers. It is also used synergistically as a blend element to modify the characteristics of other polyolefins like polypropylene and polyethylene. Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

Heated up to 190 °C and above, PB-1 can easily be compression moulded, injection moulded, blown to hollow parts, extruded, and welded. It does not tend to crack due to stress.[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.[7] It is flexible, resists impact well and has good elastic recovery.[3][8]

Isotactic polybutylene crystallizes in three different forms. Crystallization from solution yields form-III with the melting point of 106.5 °C. Cooling from the melt results in the form II which has melting point of 124 °C and density of 0.89 g/cm3. At room temperature, it spontaneously converts into the form-I with the melting point of 135 °C and density of 0.95 g/cm3.[1]

PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).[3] It shows lower resistance to aromatic and chlorinated hydrocarbons as well as oxidising acids than other polymers such as polysulfone and polyamide 6/6.[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers. It is compatible with polypropylene, ethylene propylene rubbers, and thermoplastic elastomers.

Some properties:[7]

The main use of PB-1 is in flexible pressure piping systems for hot and cold drinking water distribution, pre-insulated district heating networks and surface heating and cooling systems. ISO 15876 defines the performance requirements of PB-1 piping systems.[9] PB-1's most notable characteristics are weldability, temperature resistance, flexibility and high hydrostatic pressure resistance. The material can be classified PB 125 with a minimum required strength (MRS) of 12.5 MPa. Other features include low noise transmission, low linear thermal expansion, no corrosion and calcification.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below). The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years. In certain domestic markets, e.g. Kuwait, the United Kingdom, Korea and Spain, PB-1 piping systems have a strong position.[8]

Several PB-1 grades are commercially available for various applications and conversion technologies (blown film, cast film, extrusion coating). There are two main fields of application:

PB-1 is compatible with a wide range of tackifier resins. It offers high cohesive and adhesive strength and helps tailoring the "open time" of the adhesive (up to 30 minutes) because of its slow crystallisation kinetics. It improves the thermal stability and the viscosity of the adhesive.[10]

PB-1 accepts very high filler loadings in excess of 70%. In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments. PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

PB-1 can be foamed.[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.[12]

Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Plumbing and heating systems made from PB-1 have been used in Europe and Asia for more than 30 years. First reference projects in district heating and floor heating systems in Germany and Austria from the early 1970s are still in operation today.[8]

One example is the installation of PB-1 pipes in the Vienna Geothermal Project (1974) where aggressive geothermal water is distributed at a service temperature of 54 °C and 10 bar pressure. Other pipe materials in the same installation failed or corroded and had been replaced in the meantime.[8]

International standards set minimum performance requirements for pipes made from PB-1 used in hot water applications. Standardized extrapolation methods predict lifetimes in excess of 50 years at 70 °C and 10 bar.[8]

Polybutylene plumbing was used in several million homes built in the United States from around 1978 to 1997. Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.[13][14] The leaks were associated with degradation of polybutylene exposed to chlorinated water.[15]

Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing. The piping was removed from the acceptable for use list in the 2005 issue of the standard.[19]

In Australia in March 2023, the Department of Mines, Industry Regulation and Safety reported that Australian homes built in 2019-2020 that had used a certain brand of polybutylene piping, had become the subject of an enquiry due to the significance of water leaks reported.[20][21]

There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.[22] The reaction with chlorinated water appears to be greatly accelerated by tensile stress, and is most often observed in material under highest mechanical stress such as at fittings, sharp bends, and kinks. Localized stress whitening of the material generally accompanies and precedes decomposition of the polymer. In extreme cases, this stress-activated chemical "corrosion" can lead to perforation and leakage within a few years, but it also may not fail for decades. Fittings with a soft compression seal can give adequate service life.[further explanation needed]

Because the chemical reaction of the water with the pipe occurs inside the pipe, it is often difficult to assess the extent of deterioration. The problem can cause both slow leaks and pipe bursting without any previous warning indication. The only long-term solution is to completely replace the polybutylene plumbing throughout the entire building.[23]

Yes, they provide post-renovation support and warranties for the work they've completed. You'll have peace of mind knowing that any issues or concerns after the project can be promptly addressed by their dedicated team.

Yes, Canyon Property Projects Ltd. can help you navigate the complexities of obtaining the necessary permits and dealing with local regulations for your home improvement projects, ensuring everything's in line with local standards and requirements.

They ensure durability and longevity by using high-quality materials, employing skilled workers, and following strict construction standards. They also provide detailed planning and post-completion support to maintain the quality of their home improvement projects.