Whether you're considering elevating your curb appeal, transforming your kitchen into a luxurious space, undertaking bespoke bathroom renovations, adding sophisticated home extensions, reimagining your interior design and decor, or revitalizing your landscaping and outdoor living areas, Canyon Property Projects Ltd offers tailored solutions that meet your specific needs. We've established strong relationships with reputable suppliers, ensuring you get access to the latest and most durable materials in the market. Learn more about Kitchen Countertop Installation Surrey here Each project is approached with a unique blend of creativity and practicality, promising not only to meet but exceed your expectations. Plus, knowing that we're contributing to a healthier planet by choosing them is a huge bonus.'These testimonials speak volumes.

Their services cater to both residential and commercial clients, ensuring that no matter the size or scope of your project, you're in capable hands. You're not getting a one-size-fits-all solution; you're getting a home improvement that's as unique as your property and aspirations. That's why we're committed to not only meeting but exceeding your expectations at every step of the journey.

Instead, they go above and beyond, leveraging their deep industry knowledge and creative problem-solving skills to deliver results that not only meet but exceed your expectations. Home insulation upgrades They'll keep you updated with regular progress reports, so you're never in the dark about how your project is shaping up. Whether you're dreaming of a modern kitchen makeover, a luxurious bathroom upgrade, or an entire home renovation, their team of experienced professionals is equipped to bring your vision to life.

Their team works closely with you to ensure every project aligns with your vision and budget, making your Kitchen Countertop Installation Surrey property improvement journey as smooth as possible. Home renovation That's why they offer customized solutions that mirror your lifestyle and meet your specific needs. You'll receive detailed plans and 3D renderings, allowing you to visualize the outcome before any work begins.

Canyon Property Projects Ltd. excels in turning ordinary spaces into extraordinary living areas through innovative transformations. Kicking off your home improvement journey with Canyon Property Projects Ltd. starts with a simple phone call or email to their team. They'll transform your backyard into a personal retreat with features like custom patios, fire pits, and outdoor kitchens, all designed to enhance your home's value and your quality of life. They've streamlined their processes to avoid common delays, ensuring a smooth and swift completion of your project. You're not just hiring a company; you're partnering with a team dedicated to bringing your vision to life.

Do you envision a modern kitchen with high-tech appliances or a luxurious bathroom that serves as a private retreat? Full-service renovation Surrey Consider adding high-end fixtures, such as rainfall showerheads, heated flooring, and smart mirrors that can elevate your daily routine into an experience. Beyond customizing your space, Canyon Property Projects Ltd. also ensures that each project meets exceptional quality standards. You're embracing a lifestyle where every square inch of your property is thoughtfully designed to blend indoor comfort with the beauty of the outdoors.

You might be dreaming of a modern kitchen makeover, a luxurious bathroom upgrade, or perhaps expanding your living space with a bespoke extension. This approach hasn't only earned us the trust of homeowners across Kitchen Countertop Installation Surrey but also a reputation as a reliable and trustworthy partner in home improvement. With them, it's not just about building or renovating; it's about creating spaces that reflect your personality and lifestyle. They've built strong relationships with local suppliers, ensuring that the materials needed for your project aren't just top-notch but also readily available.

Don't forget about your front door and windows. Let's delve into what you can do. They know that no two projects are the same, which is why they've ditched the one-size-fits-all approach. This includes the project phases, materials needed, and cost estimates, ensuring transparency from the start.

Revitalize your outdoor living area with Canyon Property Projects Ltd., transforming it into a stunning extension of your home that invites relaxation and entertainment.

That's why their commitment to you doesn't end when the project does. Whether you're updating your home to better suit your lifestyle or preparing to sell, their expertise is at your disposal. Here, you're encouraged to share your ideas, style preferences, and specific requirements. From bespoke design and planning to expert craftsmanship underpinned by sustainable building practices, their approach is comprehensive. You won't just be investing in your property; you're investing in countless memories to come.

You'll find their portfolio peppered with a variety of renovations and constructions that not only enhance the aesthetics of a property but also its functionality and value.

Your preferences and the project's requirements shape the selection process. You'll find that their approach is collaborative. Moreover, they're committed to using only the highest quality materials, ensuring durability and longevity for your home improvements. At Canyon Property Projects Ltd., we understand that the foundation of any standout project lies in the selection of superior materials.

Whether you're looking to automate your lighting, climate control, security, or entertainment systems, they've got you covered.

Canyon Property Projects Ltd. consistently prioritizes sustainable building practices, ensuring your home improvement project not only looks great but also respects the environment. The quality of work and the speed of execution were outstanding. This meticulousness ensures that every aspect of your project, from the initial design to the final touches, is handled with the utmost care and precision. Their dedication to transforming your space into something you'll love is evident in every project they undertake. At Canyon Property Projects Ltd., we pride ourselves on our innovative design approach, ensuring your home improvement project not only meets but exceeds your expectations.

We understand that your home is more than just a space; it's where your life unfolds and memories are made. Specializing in both residential and commercial upgrades in Kitchen Countertop Installation Surrey, this firm claims to offer unparalleled quality and service. They listen to your ideas, preferences, and the little things that matter to you, integrating them into a cohesive design. Canyon Property Projects Ltd. doesn't just offer you a service; they offer you a partnership in making conscientious choices that align with a sustainable lifestyle. Basement waterproofing

At the heart of their approach, Canyon Property Projects Ltd believes in harmonizing form and function to elevate both the beauty and utility of a space. Whether you're eyeing a full-scale renovation or a simple refresh, they've got you covered. Each project in our portfolio is a testament to our team's dedication to transforming spaces into something truly special and personalized. Several standout projects showcase Canyon Property Projects Ltd's ability to transform homes with remarkable ingenuity and craftsmanship. Read more about Kitchen Countertop Installation Surrey here

One client couldn't stop praising how the team transformed their outdated kitchen into a modern, functional space that's now the heart of their home. Let's take a closer look at what makes them stand out in the crowded field of home improvement. They've got a knack for anticipating challenges before they become problems, ensuring that your project stays on track.

You can rest easy knowing you've selected a partner who values your satisfaction as much as you do. It's clear that Canyon Property Projects Ltd doesn't just renovate homes; they reinvent them, ensuring every project reflects the homeowner's personality and meets their needs.

| |

| Names | |

|---|---|

| Other names

polybutene-1, poly(1-butene), PB-1

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.111.056 |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C4H8)n | |

| Density | 0.95 g/cm3[1] |

| Melting point | 135 °C (275 °F; 408 K)[1] |

| Related compounds | |

Related compounds

|

1-butene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

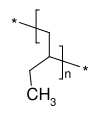

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.[2]

Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts.

Isotactic PB-1 is produced commercially using two types of heterogeneous Ziegler–Natta catalysts.[3] The first type of catalyst contains two components, a solid pre-catalyst, the δ-crystalline form of TiCl3, and solution of an organoaluminum cocatalyst, such as Al(C2H5)3. The second type of pre-catalyst is supported. The active ingredient in the catalyst is TiCl4 and the support is microcrystalline MgCl2. These catalysts also contain special modifiers, organic compounds belonging to the classes of esters or ethers. The pre-catalysts are activated by combinations of organoaluminum compounds and other types of organic or organometallic modifiers. Two most important technological advantages of the supported catalysts are high productivity and a high fraction of the crystalline isotactic polymer they produce at 70–80 °C under standard polymerization conditions.[4][5][6]

PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

PB-1, when applied as a pure or reinforced resin, can replace materials like metal, rubber and engineering polymers. It is also used synergistically as a blend element to modify the characteristics of other polyolefins like polypropylene and polyethylene. Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

Heated up to 190 °C and above, PB-1 can easily be compression moulded, injection moulded, blown to hollow parts, extruded, and welded. It does not tend to crack due to stress.[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.[7] It is flexible, resists impact well and has good elastic recovery.[3][8]

Isotactic polybutylene crystallizes in three different forms. Crystallization from solution yields form-III with the melting point of 106.5 °C. Cooling from the melt results in the form II which has melting point of 124 °C and density of 0.89 g/cm3. At room temperature, it spontaneously converts into the form-I with the melting point of 135 °C and density of 0.95 g/cm3.[1]

PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).[3] It shows lower resistance to aromatic and chlorinated hydrocarbons as well as oxidising acids than other polymers such as polysulfone and polyamide 6/6.[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers. It is compatible with polypropylene, ethylene propylene rubbers, and thermoplastic elastomers.

Some properties:[7]

The main use of PB-1 is in flexible pressure piping systems for hot and cold drinking water distribution, pre-insulated district heating networks and surface heating and cooling systems. ISO 15876 defines the performance requirements of PB-1 piping systems.[9] PB-1's most notable characteristics are weldability, temperature resistance, flexibility and high hydrostatic pressure resistance. The material can be classified PB 125 with a minimum required strength (MRS) of 12.5 MPa. Other features include low noise transmission, low linear thermal expansion, no corrosion and calcification.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below). The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years. In certain domestic markets, e.g. Kuwait, the United Kingdom, Korea and Spain, PB-1 piping systems have a strong position.[8]

Several PB-1 grades are commercially available for various applications and conversion technologies (blown film, cast film, extrusion coating). There are two main fields of application:

PB-1 is compatible with a wide range of tackifier resins. It offers high cohesive and adhesive strength and helps tailoring the "open time" of the adhesive (up to 30 minutes) because of its slow crystallisation kinetics. It improves the thermal stability and the viscosity of the adhesive.[10]

PB-1 accepts very high filler loadings in excess of 70%. In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments. PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

PB-1 can be foamed.[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.[12]

Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Plumbing and heating systems made from PB-1 have been used in Europe and Asia for more than 30 years. First reference projects in district heating and floor heating systems in Germany and Austria from the early 1970s are still in operation today.[8]

One example is the installation of PB-1 pipes in the Vienna Geothermal Project (1974) where aggressive geothermal water is distributed at a service temperature of 54 °C and 10 bar pressure. Other pipe materials in the same installation failed or corroded and had been replaced in the meantime.[8]

International standards set minimum performance requirements for pipes made from PB-1 used in hot water applications. Standardized extrapolation methods predict lifetimes in excess of 50 years at 70 °C and 10 bar.[8]

Polybutylene plumbing was used in several million homes built in the United States from around 1978 to 1997. Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.[13][14] The leaks were associated with degradation of polybutylene exposed to chlorinated water.[15]

Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing. The piping was removed from the acceptable for use list in the 2005 issue of the standard.[19]

In Australia in March 2023, the Department of Mines, Industry Regulation and Safety reported that Australian homes built in 2019-2020 that had used a certain brand of polybutylene piping, had become the subject of an enquiry due to the significance of water leaks reported.[20][21]

There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.[22] The reaction with chlorinated water appears to be greatly accelerated by tensile stress, and is most often observed in material under highest mechanical stress such as at fittings, sharp bends, and kinks. Localized stress whitening of the material generally accompanies and precedes decomposition of the polymer. In extreme cases, this stress-activated chemical "corrosion" can lead to perforation and leakage within a few years, but it also may not fail for decades. Fittings with a soft compression seal can give adequate service life.[further explanation needed]

Because the chemical reaction of the water with the pipe occurs inside the pipe, it is often difficult to assess the extent of deterioration. The problem can cause both slow leaks and pipe bursting without any previous warning indication. The only long-term solution is to completely replace the polybutylene plumbing throughout the entire building.[23]

| |

| Names | |

|---|---|

| Other names

polybutene-1, poly(1-butene), PB-1

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.111.056 |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C4H8)n | |

| Density | 0.95 g/cm3[1] |

| Melting point | 135 °C (275 °F; 408 K)[1] |

| Related compounds | |

Related compounds

|

1-butene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

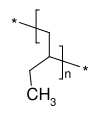

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.[2]

Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts.

Isotactic PB-1 is produced commercially using two types of heterogeneous Ziegler–Natta catalysts.[3] The first type of catalyst contains two components, a solid pre-catalyst, the δ-crystalline form of TiCl3, and solution of an organoaluminum cocatalyst, such as Al(C2H5)3. The second type of pre-catalyst is supported. The active ingredient in the catalyst is TiCl4 and the support is microcrystalline MgCl2. These catalysts also contain special modifiers, organic compounds belonging to the classes of esters or ethers. The pre-catalysts are activated by combinations of organoaluminum compounds and other types of organic or organometallic modifiers. Two most important technological advantages of the supported catalysts are high productivity and a high fraction of the crystalline isotactic polymer they produce at 70–80 °C under standard polymerization conditions.[4][5][6]

PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

PB-1, when applied as a pure or reinforced resin, can replace materials like metal, rubber and engineering polymers. It is also used synergistically as a blend element to modify the characteristics of other polyolefins like polypropylene and polyethylene. Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

Heated up to 190 °C and above, PB-1 can easily be compression moulded, injection moulded, blown to hollow parts, extruded, and welded. It does not tend to crack due to stress.[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.[7] It is flexible, resists impact well and has good elastic recovery.[3][8]

Isotactic polybutylene crystallizes in three different forms. Crystallization from solution yields form-III with the melting point of 106.5 °C. Cooling from the melt results in the form II which has melting point of 124 °C and density of 0.89 g/cm3. At room temperature, it spontaneously converts into the form-I with the melting point of 135 °C and density of 0.95 g/cm3.[1]

PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).[3] It shows lower resistance to aromatic and chlorinated hydrocarbons as well as oxidising acids than other polymers such as polysulfone and polyamide 6/6.[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers. It is compatible with polypropylene, ethylene propylene rubbers, and thermoplastic elastomers.

Some properties:[7]

The main use of PB-1 is in flexible pressure piping systems for hot and cold drinking water distribution, pre-insulated district heating networks and surface heating and cooling systems. ISO 15876 defines the performance requirements of PB-1 piping systems.[9] PB-1's most notable characteristics are weldability, temperature resistance, flexibility and high hydrostatic pressure resistance. The material can be classified PB 125 with a minimum required strength (MRS) of 12.5 MPa. Other features include low noise transmission, low linear thermal expansion, no corrosion and calcification.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below). The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years. In certain domestic markets, e.g. Kuwait, the United Kingdom, Korea and Spain, PB-1 piping systems have a strong position.[8]

Several PB-1 grades are commercially available for various applications and conversion technologies (blown film, cast film, extrusion coating). There are two main fields of application:

PB-1 is compatible with a wide range of tackifier resins. It offers high cohesive and adhesive strength and helps tailoring the "open time" of the adhesive (up to 30 minutes) because of its slow crystallisation kinetics. It improves the thermal stability and the viscosity of the adhesive.[10]

PB-1 accepts very high filler loadings in excess of 70%. In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments. PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

PB-1 can be foamed.[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.[12]

Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Plumbing and heating systems made from PB-1 have been used in Europe and Asia for more than 30 years. First reference projects in district heating and floor heating systems in Germany and Austria from the early 1970s are still in operation today.[8]

One example is the installation of PB-1 pipes in the Vienna Geothermal Project (1974) where aggressive geothermal water is distributed at a service temperature of 54 °C and 10 bar pressure. Other pipe materials in the same installation failed or corroded and had been replaced in the meantime.[8]

International standards set minimum performance requirements for pipes made from PB-1 used in hot water applications. Standardized extrapolation methods predict lifetimes in excess of 50 years at 70 °C and 10 bar.[8]

Polybutylene plumbing was used in several million homes built in the United States from around 1978 to 1997. Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.[13][14] The leaks were associated with degradation of polybutylene exposed to chlorinated water.[15]

Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing. The piping was removed from the acceptable for use list in the 2005 issue of the standard.[19]

In Australia in March 2023, the Department of Mines, Industry Regulation and Safety reported that Australian homes built in 2019-2020 that had used a certain brand of polybutylene piping, had become the subject of an enquiry due to the significance of water leaks reported.[20][21]

There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.[22] The reaction with chlorinated water appears to be greatly accelerated by tensile stress, and is most often observed in material under highest mechanical stress such as at fittings, sharp bends, and kinks. Localized stress whitening of the material generally accompanies and precedes decomposition of the polymer. In extreme cases, this stress-activated chemical "corrosion" can lead to perforation and leakage within a few years, but it also may not fail for decades. Fittings with a soft compression seal can give adequate service life.[further explanation needed]

Because the chemical reaction of the water with the pipe occurs inside the pipe, it is often difficult to assess the extent of deterioration. The problem can cause both slow leaks and pipe bursting without any previous warning indication. The only long-term solution is to completely replace the polybutylene plumbing throughout the entire building.[23]

When project delays or unexpected issues pop up during construction, Canyon Property Projects Ltd. promptly addresses them. They'll communicate with you, propose solutions, and adjust plans to minimize disruptions and keep your project on track.

Yes, Canyon Property Projects Ltd. offers warranties and guarantees on both their workmanship and the materials used in your home improvement project. You'll have peace of mind knowing your investment is protected.

Canyon Property Projects Ltd. offers various financing options and payment plans to help you manage your home improvement project costs. You'll find flexible solutions tailored to fit your budget, making your project more manageable.